Our Services

Turnkey Outage, Outage Planning and Inspection Services

Powerhouse Technology, Inc. services our customers in their practical use and installation of our products. We offer turnkey outage support, outage planning and stoker inspections. If hired for a turnkey outage; our technical service specialists will provide:

- Evaluation of your site and needs to make recommendations regarding replacement parts.

- Pre-outage inspection to ensure that all necessary parts & personnel are on site before work begins.

- Replacement parts for all for the outage needs.

- Outage Specialist on site to supervise the removal and installation of the parts.

- During the outage, our staff will ensure the parts are properly installed and tested before start-up of your system.

Casting Production

Powerhouse Technology supplies castings in any ferrous and non-ferrous alloy. Some of the common alloys produced by Powerhouse are temperature resistant cast iron, temperature resistant ductile iron, high temperature steel, and high temperature stainless steel.

Maintenance and Repairs

Whether it is routine maintenance or emergency repairs, our technical service specialists provide everything from design, site supervision, and labor to quality replacement parts for getting the job done properly and on time. We’ll provide the service necessary to get your system back on line right when you need it. Complete and submit a Maintenance Request form here.

Reverse Engineering

We can take your old part and make it into a working part through reverse engineering. Our highly trained and experienced engineering staff can take a drawing or part and prepare it for production.

Quality Control

Our quality control staff has practical and theological experience with castings, fabrications and forgings. We have in house metallurgy testing, CMM machines and a host of measurement tools to ensure we are delivering quality parts. Our QC department can take the place of your internal quality if needed.

Material/Failure Analysis

Our staff is highly trained on metallurgy and the chemical reactions under heat and stress to ensure the correct material is being used under the right application/environment. We have in house metallurgy testing and the ability to conduct physical testing as needed.

Pattern Making Capabilities

We produce industrial patterns for castings from wood, iron, aluminum, and urethane. Working in conjunction with foundries, we can provide a cost-effective solution of the highest quality that fits the customer‘s needs.

Stocking/Inventory Solutions

Powerhouse Technology, Inc. has over 75 acres of land and several warehouse locations to assist you in keeping inventory readily available. We have climate controlled facilities as well as cold storage that can be an inventory option for your tight space.

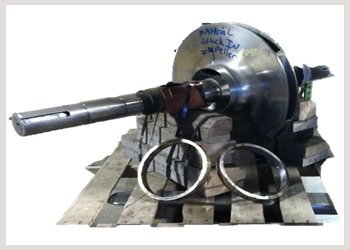

Equipment Rebuilding

Our staff of master mechanics can rebuild all types of combustion, ash handling and fuel handling systems. We can perform on-site work, as well as in-house repairs; our staff has extensive knowledge and expertise in working with products produced by major manufacturers. Additionally, we have vast experience rebuilding and repairing process equipment in the food, brewery, and chemical industries.

Some of Our Specialties

- Turnkey Outages

- Outage Planning

- Stoker Inspections

- Engineering Support

- Reverse Engineering

- Equipment Rebuilding

- Special Welding/Hard Facing

- Material Analysis

- Failure Analysis

- Dynamic/Static Balancing

- Precision Pattern Making

- Quality Control

- Guaranteed Inventory

- Consignment